The Ultimate Guide to Choosing the Best Linen Shirt Manufacturers for Top Linen Brands

- Share

- Issue Time

- Oct 28,2025

Summary

Discover how to choose the best linen shirt manufacturers and why partnering with Linenwind ensures sustainable, stylish, and scalable production for top brands.

Introduction

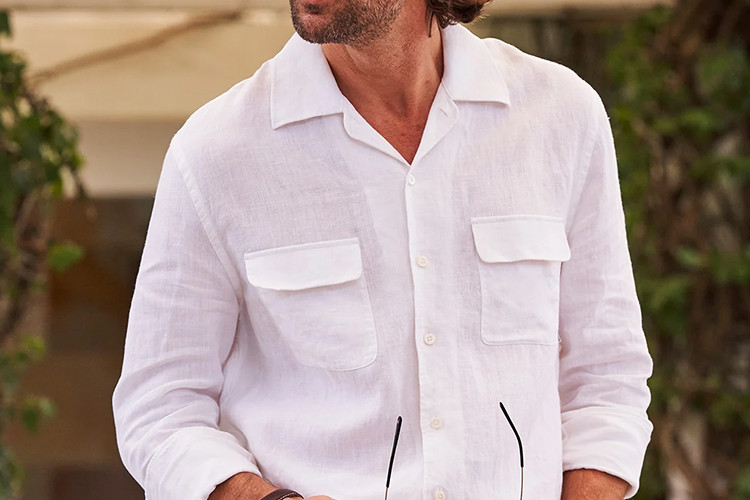

In a market increasingly driven by sustainability, natural fibres, and premium craftsmanship, the role of specialised linen shirt manufacturers has never been more critical. For brands seeking to launch or expand linen collections, choosing the right partner is not simply about finding capacity — it’s about aligning on quality, traceability, design agility, and eco-credentials. This ultimate guide, The Ultimate Guide to Choosing the Best Linen Shirt Manufacturers for Top Linen Brands, is designed for brand managers, private-label designers and founders who understand that success begins with manufacturing excellence. In the sections that follow, we’ll explore how linen shirts fit into the 2025 trend landscape, what criteria you should apply when evaluating linen shirt manufacturers, and how our own company, Linenwind, stands out as a strategic partner. By the end of this guide you’ll be equipped to assess manufacturers with clarity and confidence.

Why Linen Shirts Are a Strategic Category for Brands

When it comes to product categories, linen shirts occupy a sweet spot: they combine timeless style, performance benefits (noticeably breathability and durability), and premium positioning — especially when executed well. For linen-focused brands or those pivoting toward natural-fibre collections, working with experienced linen shirt manufacturers is essential.

Here are the key reasons linen shirts are strategic.

Natural appeal & consumer demand: Modern consumers increasingly seek authentic materials and transparent sourcing. Linen’s credentials as a sustainable, breathable fabric give brands a narrative advantage.

Versatility and seasonality: Linen shirts transition effortlessly across spring, summer, and resort collections. Unlike heavier outerwear, they offer a broad window of wear and appeal.

Brand differentiation potential: While many brands may add a “linen shirt” SKU, fewer do so with premium fabrics, thoughtful design details, and responsible manufacturing. Partnering with capable linen shirt manufacturers elevates your offering.

Private-label and OEM growth: Brands launching linen lines often require low minimums, adaptive production, and custom branding — capabilities offered by specialist linen shirt manufacturers rather than generic cut & sew factories.

Sustainability story and premium pricing: A well-made linen shirt allows brands to command premium price points and tell a compelling sustainable story. But this is only possible with manufacturers who understand linen’s unique behaviour (shrinkage, drape, finishing).

For these reasons, evaluating and selecting the right linen shirt manufacturers becomes a strategic enabler — not just a sourcing decision.

What to Look for When Selecting Linen Shirt Manufacturers

When you’re comparing factories, the difference between a good linen shirt and a great linen shirt comes down to detail and partnership. Below is a structured checklist of criteria to apply when vetting potential linen shirt manufacturers.

Fabric Expertise & Traceability

Your manufacturing partner must deeply understand linen fabric properties — from flax origin, fibre length, weaving method, weight, finishing and shrinkage behaviour. For example, industry buyers emphasise that linen derived from long-fibre European flax produces smoother, more durable shirts.

Ask about certifications (OEKO-TEX, European Flax®), mill sources and whether the manufacturer performs pre-shrinking or enzyme-wash treatments to control dimensional stability.

Design & Sampling Capabilities

Not all shirt factories handle linen the same way. The best linen shirt manufacturers offer full OEM/ODM services: tech-packs, CAD patterns, rapid prototyping, fit iterations and sample approval cycles. They understand that linen shirts require different cuts and finishes compared to cotton, e.g., allowances for fabric behaviour, collar/styling suited for natural fibres.

Minimum Order Quantities (MOQs) & Flexibility

For brands testing new lines or launching small collections, low MOQs are a major advantage. A manufacturer who only accepts large runs may restrict agility. One credible assessment states that the right partner must support “small-batch runs” without sacrificing quality.

Quality Assurance & Communication

Reading the production process doesn’t matter if there’s no quality control. The top linen shirt manufacturers integrate real-time inspection, inline checks, final garment audits and transparent communication. According to a manufacturing guide, continuous monitoring “ensures only flawless linen shirts reach the market”.

Sustainability & Ethical Production

Today’s buyers expect more than good looks. Eco-credentials and ethical manufacturing matter. A strong manufacturer commits to responsible sourcing, low-impact finishing, wastewater controls and improved labour standards. Many brands hold their manufacturing partners to these standards when selecting linen shirt manufacturers.

Lead Time, Capacity & Reliability

Launching a collection on schedule depends on a reliable partner. Check the factory’s production capacity for linen shirt manufacturing, responsiveness to small orders and ability to scale. Ask for client references, on-time delivery performance and whether they can handle design changes or reorder runs.

Private Label Support & Finishing Services

Beyond shirt production, private-label brands require custom labels, trims, packaging, brand tags and logistics support. A manufacturer that offers full service — from design to shipment — is valuable. For brands working with linen shirt manufacturers, this full-package support distinguishes average factories from strategic partners.

Linenwind – Your Trusted Partner Among Linen Shirt Manufacturers

At Linenwind, we take pride in being one of the leading linen shirt manufacturers in China, delivering full-service OEM and ODM solutions for top linen brands worldwide.

About Us

About Us

With over 20 years of apparel manufacturing experience, we’ve mastered the art of transforming natural linen into high-end, wearable fashion. From sourcing European flax fabrics to implementing precision cutting and stitching, our production line blends craftsmanship with sustainability.

Why Brands Choose Linenwind

Eco-friendly & sustainable production: We prioritise organic linen fibres, low-impact dyes, and energy-efficient finishing, aligning with eco-conscious brand values.

Full in-house OEM & ODM services: Every step — design, pattern development, sampling, production, packaging — is completed under one roof.

Low MOQ of 60 pieces: Ideal for startups and boutique brands testing new linen shirt concepts or limited collections.

Rigorous quality assurance: Inline inspections and real-time communication keep clients informed through every stage.

Dedicated account managers: We maintain personal, transparent communication channels to ensure deadlines and quality standards are consistently met.

At Linenwind, we view each collaboration not as a transaction but as a shared journey. Our role is to help you create timeless linen shirts that elevate your brand while protecting the planet.

Why Choosing the Right Linen Shirt Manufacturer Shapes Brand Success

The difference between a great linen shirt and a forgettable one often lies behind the scenes — in how it’s made. Here’s why partnering with the right linen shirt manufacturers determines your brand’s long-term success.

Product Consistency & Brand Trust

Consistency is currency. When customers buy your linen shirts, they expect identical fit, feel and finish each time. Only established linen shirt manufacturers with strict process control can deliver that reliability.

Design Innovation & Custom

Fast-moving fashion cycles demand innovation. A capable manufacturer helps your team translate creative ideas into precise patterns, prototypes and small-batch samples quickly — without compromising on sustainability.

Sustainability as Brand Value

Eco-responsibility isn’t a buzzword anymore — it’s a brand differentiator. Working with sustainable linen shirt manufacturers allows you to integrate authentic eco narratives into your marketing, appealing to the growing segment of conscious consumers.

Cost Transparency & Efficiency

The right partner explains cost drivers — fabric grade, washing, trims — and provides transparent quotations. This builds mutual trust and eliminates hidden surprises in production.

Scaling Without Losing Agility

You might start with 60 pieces but scale to 6,000 as your line grows. Linenwind’s integrated systems, from CAD to automated sewing, ensure that scaling doesn’t compromise quality.

Partnership Mindset

Beyond machinery, the best manufacturers act as partners — offering guidance, foresight, and technical expertise. They collaborate on sustainability goals and timeline planning.

At Linenwind, we combine technical excellence with this partnership mindset. We know that your success as a brand directly mirrors our own reputation among global linen shirt manufacturers.

How Linenwind Works — Our OEM & ODM Process Explained

Partnering with Linenwind means gaining a transparent, full-cycle production experience. Here’s how we make collaboration effortless for global clients.

Step 1 – Concept & Consultation

We start by understanding your brand vision — target market, fabric preferences, silhouettes, and budget. This step defines the foundation of your linen shirt collection.

Step 2 – Fabric Development

We source premium 100 % European flax linen or high-performance blends, offering swatches with various weights, textures, and washes. Our R&D team tests shrinkage, tensile strength, and colourfastness to ensure fabric durability.

Step 3 – Design & Sampling

Our in-house pattern-makers create digital patterns and prototypes based on your sketches or technical packs. Samples are produced within days for approval. Adjustments can be made instantly with CAD updates.

Step 4 – Quality Control Plan

Before mass production, we outline QA checkpoints: cutting precision, stitching consistency, seam strength, and finishing standards. Each batch is documented through digital tracking.

Step 5 – Production & Packaging

Our production floor integrates modern sewing units, eco-friendly washing, and final pressing stations. Every linen shirt is finished, pressed, and packed according to your private-label guidelines.

Step 6 – Logistics & After-Sales

We coordinate delivery timelines, export documentation, and shipping from our facility. Even after dispatch, your account manager remains in touch for feedback or reorder adjustments.

By managing every stage internally, we maintain the control and precision that premium linen shirts require — and ensure that no design intent is lost between departments.

Case Studies: How Top Brands Work with Linen Shirt Manufacturers

Real-world success stories show how choosing the right linen shirt manufacturers transforms creative ideas into commercial results.

European Minimalist Brand

A boutique label in Copenhagen wanted relaxed-fit men’s linen shirts for its 2024 summer line. They approached us at Linenwind for a short run of 120 pieces. Our team advised on fabric weight (150 gsm pre-washed European flax), pattern adjustments for a drapier silhouette, and natural corozo buttons. The line sold out within six weeks, prompting triple the volume.

Australian Resortwear Startup

A start-up from Byron Bay needed women’s linen shirts with embroidered logos and organic dye. With our low MOQ of 60 pieces, we provided three sample rounds within ten days and full delivery in four weeks. The brand gained placement in two resort boutiques and became a returning client.

U.S. Lifestyle Retailer

A large North American retailer required a private-label linen shirt range for its eco collection. They needed consistent quality across thousands of units. Linenwind’s automated cutting and real-time QA system ensured 98 % on-time delivery and under 1 % defect rate.

These cases demonstrate how partnering with experienced custom linen shirt manufacturers allows both emerging and established brands to respond quickly to market demand while maintaining sustainable production standards.

Global Market Outlook for Linen Shirts 2025–2028

Rising Demand

Industry research from Fibre2Fashion predicts the linen apparel market will exceed USD 17 billion by 2028, driven by eco-conscious consumers and resortwear trends. Shirts remain the top category because they bridge formal and casual wear.

Regional Shifts

China remains the production hub for global linen shirt manufacturers, thanks to advanced machinery and vertical integration, while European brands lead design innovation. Brands sourcing from partners such as Linenwind benefit from both cost efficiency and sustainability compliance (ISO 9001 & BSCI).

Sustainable Growth

Eco certifications and circular fashion initiatives are setting new benchmarks. Retailers increasingly request traceable supply chains — a standard practice in our own facility. We recycle 70 % of process water and use energy-saving dye systems.

The Trend Cycle

From relaxed unisex fits to minimalist utility shirts, linen continues to dominate spring/summer assortments. As consumers embrace breathable natural fabrics, working with expert linen shirt manufacturers ensures brands can meet demand without overproduction.

Buying Checklist: Questions to Ask Your Linen Shirt Manufacturer

Before you sign a contract, use this quick evaluation checklist to identify reliable linen shirt manufacturers:

What certifications do you hold? → Look for OEKO-TEX or BSCI.

Can you support low MOQ orders? → Linenwind starts from 60 pieces.

Do you pre-wash or shrink-test fabrics? → Pre-washing prevents sizing issues.

Can I visit or request a virtual factory tour? → Transparency builds trust.

How long is the sampling lead time? → Our standard is 7–10 days.

What packaging options are sustainable? → We use recycled paper, compostable bags.

Do you provide digital pattern files? → Essential for consistency across seasons.

How do you handle reorders or urgent replenishments? → Ask about priority lines.

Can you integrate my private label requirements? → Yes—logos, trims, tags, gift boxes.

How do you communicate production progress? → Choose manufacturers offering real-time dashboards or regular photo updates.

By following this list, you’ll filter vendors that lack transparency or technical depth — and prioritise those, like Linenwind, that align with modern quality and sustainability expectations.

Conclusion – Partnering with Linenwind for Sustainable Success

In a rapidly evolving fashion landscape, brands that prioritise sustainability, agility, and craftsmanship will lead the market. Choosing the best linen shirt manufacturers i, therefore, one of the most impactful strategic decisions a brand can make.

At Linenwind, we combine two decades of garment expertise with a clear mission: to create beautiful, durable linen shirts through responsible production. From eco-certified fabrics and in-house OEM/ODM capability to personalised client communication, we offer end-to-end control that few manufacturers can match.

Whether you’re a startup testing your first 60-piece capsule or a global label scaling a resort collection, we ensure every shirt meets international quality and ethical standards.

Visit our Custom Linen Shirts Collection, explore our OEM & ODM Service, and reach us via Contact Us to start your journey.

Together, let’s redefine what modern linen fashion can be — authentic, sustainable, and built on trust.