Communicating Design Details to Your Custom Linen Dress Manufacturer (Avoiding Misunderstandings)

- Share

- Issue Time

- Oct 9,2025

Summary

Learn how to communicate design details effectively with your custom linen dress manufacturer to avoid costly errors and improve production accuracy.

Introduction: Poor Communication Leads to Costly Mistakes

In the world of custom apparel, one mis-specified seam or ambiguous dart placement can cost you thousands in rework, delay your launch, or generate bulk units of unsellable garments. When working on a Custom Linen Dress project, the margin for such mistakes is even slimmer—linen is a natural fiber with its own quirks (shrinkage, weave direction, drape). To succeed, you need clear, precise, and deliberate communication with your manufacturer.

At Linenwind, we’ve seen many early-stage fashion brands stumble not because their designs were weak, but because their technical briefs were vague. Over my 20 years in the clothing industry, I (representing Linenwind) have learned that great communication—not just talent or vision—is the difference between a successful first production run and costly failure.

In this article, I’ll walk you through how to effectively communicate every design detail to your custom linen dress manufacturer (such as us), to avoid misunderstandings, streamline sampling, and maintain quality from first sample to bulk. Throughout, I’ll refer to how Linenwind’s OEM & ODM services support this process, and provide you with tangible templates you can use.

Must-Have Communication Assets

To avoid misunderstandings when producing a Custom Linen Dress, you must equip your manufacturer with a set of key technical assets. Below are the essentials:

1. Tech Pack (Technical Specification Pack)

A tech pack is your blueprint. It includes:

Front/back flat sketches (line drawings) with all views (front, back, side)

Annotations for every design detail (pleats, gathers, flare, trims, pockets)

Bill of Materials (BOM): fabrics, linings, interfacing, trims, thread colors

Stitching information and seam allowances

Construction sequence notes

Trim specs (zippers, buttons, snaps, labels)

Without a solid tech pack, the manufacturer will make assumptions — often assumptions that differ from your vision.

2. Hand Sketches / Illustrator Files

Even if simplified, sketches help clarify your intent—especially custom style lines, dart shapes, and design flair. I recommend sending both a polished vector file (e.g. Adobe Illustrator) plus a concept sketch with notes. This dual-layer helps avoid misinterpretation.

3. Measurement Table (Grading Spec Sheet)

List all critical measurements (bust, waist, hip, length, sleeve length, cuff width, hem width, etc.) for each size. Specify tolerances (± X cm). For linen dresses, also indicate whether the garment is meant to be relaxed-fit or snug (linen’s lack of stretch requires clarity).

4. Photo References / Real Garment Samples

If possible, include reference photos of dresses with similar features (pleats, bias cut, trims) and even a mock-up or prototype sample. These visual cues reduce ambiguity and help your manufacturer “see what you mean” rather than relying solely on textual instruction.

5. Fabric Swatches and Test Reports

Include small swatches of your chosen linen fabrics (with grain direction marked), and any test reports (shrinkage, color fastness). For linen, pre-washing shrinkage is critical; communicate expected percentage shrinkage after wash.

How to Explain Tricky Points

Even with all assets in hand, some details need extra care in explanation. Below are common tricky areas for a Custom Linen Dress, with suggestions on how to communicate them clearly.

Seam Allowances

Indicate seam allowance widths on each seam (e.g. 1 cm, 1.5 cm, 2 cm).

Clarify whether allowances are “included” (meaning the pattern already accounts for the extra fabric) or “not included” (to be added).

For linen, you may want to allow more room for raw-edge finishing, edge-stitching, or topstitching tolerances.

Dart Positions & Shapes

Show both the dart point location (how many cm down from shoulder, etc.) and dart intake width.

Annotate whether darts are pressed toward the side seam, or twin-needle stitched top to bottom.

Use arrows or callouts to show fold lines, stitch end points, and direction of pressing.

Facing / Lining / Interfacing Methods

If you use facings, show whether they are full, partial, bias, or shaped.

Label stay stitching lines, clipping notches, and direction of attaching.

For linen, interfacing choice is delicate — specify whether you prefer fusible or sewn-in, and whether you want organza, cotton, or lightweight knit interfacing.

If a style uses a lining, clarify whether you want a full lining or partial under-bodice lining, and whether the lining edge is hidden or visible.

Edge Finishing (Hems, Raw Edges, French Seams)

Clarify hem depth and whether it is double-fold, blind-hem, or rolled.

For lightweight linen, if you require French seams or flat-felled seams, annotate them explicitly.

Indicate whether you want overlocking (serging), binding, or taped finishes at internal seams.

Special Details: Pockets, Slits, Pleats, Gathers

For patch/side/inseam pockets: show pocket bag sizes, opening width, reinforcement stitches.

For side slits or vents: show slit length, overlap width, finishing method (double-stitch, bar tack, facing).

For pleats/gathers: indicate pleat depth, spacing (pitch), and whether they’re stitched down partially.

Whenever possible, include small callout boxes in your sketches or tech pack, and highlight these areas visually. Red arrows, color highlights, and zoomed-in callout sketches all help reduce ambiguity.

Change Control & Revision Management

Design and specification changes often happen after initial sampling or feedback. But uncontrolled changes lead to confusion. To maintain clarity:

Use Version Control

Label every tech pack or revision with a version number or date (e.g. v1.0, v2.1, v3_2025-10-08).

Maintain a log sheet of changes (what changed, why, and who approved).

Never overwrite the original file without preserving the prior version.

Highlight Changes

Use red or highlighted text/boxes to draw attention to what has changed (e.g. “In v2.0, seam allowance changed from 1 cm → 1.2 cm”).

In revision calls, summarize changes in your change log for easy reference.

Freeze Before Bulk

After you approve a final pre-production sample (PPS), clearly mark that the design is “frozen” (no further changes allowed unless critical).

Anything beyond that (especially weight/trim/color changes) must go through a formal approval round with updated samples and sign-off.

Communication Channels & Accountability

Use a consistent system (e.g. shared Google Drive, Dropbox, or Manufacturer’s cloud portal) where the latest documents reside.

Assign a single point of contact (POC) on your team and one at your manufacturer to avoid “version conflicts.”

Always date-stamp and time-stamp communications (e.g. “On Oct 8, 2025 at 14:23, revised hemstitch detail sent”).

By imposing disciplined change control, you reduce errors, version mismatch, and misinterpretation across your team and the manufacturer.

Use of Pictures / Real Samples / Mockups

Visual evidence is one of the strongest tools you can use to avoid misunderstandings. Here’s how to integrate pictures and mockups into your communication for a Custom Linen Dress:

Photograph Key Areas of a Physical Sample

Use close-up shots (with ruler or scale) to show stitching, dart tips, finishing edges, seam widths, facings, etc.

Use annotated overlays (e.g. arrows, circles, color highlights) to point out what you want emphasized or changed.

Include both right side and wrong side (interior) shots.

3D Mockups or Garment-on-Model

Use realistic 3D renderings or drape mockups to show how the dress should look when worn (fit, silhouette).

This helps the factory understand your design intent (not just flat sketches).

Prototype / Toile / Muslin Test

If possible, provide a muslin (or linen mock-up) sample with clear markings, such as center front, bust apex, grainline.

When the manufacturer receives this, they can align pattern interpretation with your expectations.

Annotated Callouts

On images, use callouts with labels (e.g. “Buttonhole here, 1.2 cm from edge”) or “Overlap 25 mm.”

Provide side-by-side comparison: your reference image vs sample image, with labels showing difference.

(Image suggestion note: A close-up mockup photo with annotations of seam allowance, dart, facing.

Prompt: “High-resolution close-up of linen dress sample interior seam, annotated arrows and text overlay indicating seam allowance, dart intake, facing edge.”)

In our projects at Linenwind, we often exchange sample images back and forth with clients in this way. This visual back-and-forth dramatically reduces ambiguity and helps align expectations before going into mass production.

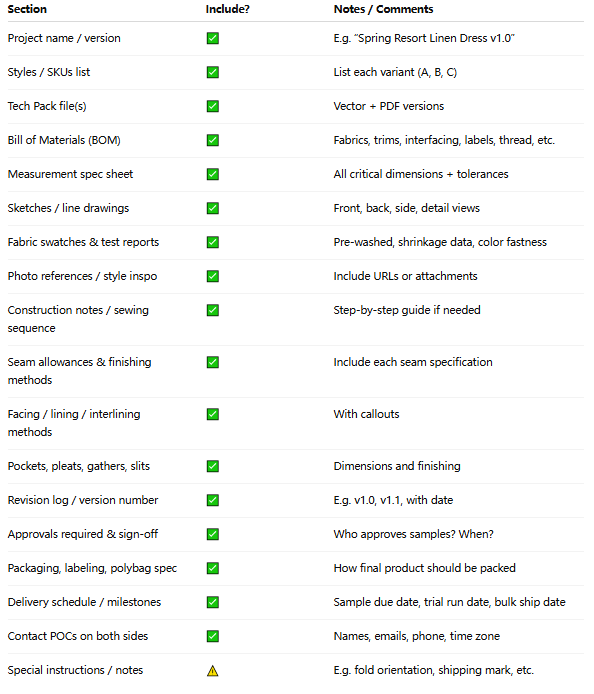

Communication Templates / Briefing Checklists

To streamline and standardize your communication, here is a recommended briefing checklist template for your first-round brief to your custom linen dress manufacturer. You can adapt it for follow-up revisions.

Manufacturer Briefing / Design Communication Checklist

Use this as your baseline for every design you send. Ideally, include this table (or a variation) within each design communication package.

Common Misunderstandings Between Brands and Manufacturers

Even when both the designer and the factory have good intentions, small misunderstandings can snowball into large production issues. Here are the most common communication pitfalls we’ve observed over 20 years in custom linen manufacturing — and how to prevent them.

1. Unclear Fabric Specifications

Linen fabrics vary drastically in weight, weave, and finish. A “medium-weight linen” could mean 160 gsm to one supplier and 220 gsm to another. Always specify:

Fabric composition (100 % linen, or linen-cotton blend)

Weight in GSM (grams per square meter)

Weave type (plain, twill, herringbone)

Finish (washed, bleached, dyed, printed, stone-washed)

At Linenwind, we always confirm these specs through swatch approval before bulk cutting. Our internal QC team double-checks weight and shrinkage after pre-wash to ensure your Custom Linen Dress feels exactly as intended.

2. Missing Shrinkage Allowances

Natural linen can shrink 2–6 % after washing. If this isn’t accounted for in the pattern, your dress may end up shorter than expected. Provide your manufacturer with target post-wash dimensions and fabric test results.

3. Vague Color Communication

Never rely on photos alone. Lighting conditions can alter linen tones significantly. Use Pantone TCX or physical lab-dips for color confirmation. At Linenwind, we send digital and physical swatches before dyeing bulk fabric.

4. Different Terminology

Fashion terminology varies internationally — what you call a “bias binding,” some may call “edge tape.” To avoid confusion, supplement every term with a diagram or labeled image.

5. Assumed Construction Techniques

Designers often assume the factory will “know” how to assemble something. Yet one manufacturer may serge edges, another may use binding. Specify construction expectations explicitly.

By systematically addressing these misunderstandings, you can eliminate 80 % of sampling errors before they occur.

Real-World Example — How Clear Communication Saved a Collection

To illustrate the impact of communication, here a real example from our experience at Linenwind.

A European resort-wear brand approached us to develop a Custom Linen Dress collection featuring asymmetrical hems and elasticized waist details. They sent inspiration photos but no annotated measurements or seam allowances. The first prototype didn’t meet their expectations: the waist placement was off 2 cm, and the skirt drape was uneven.

After discussing the issue, we implemented a structured tech-pack system and introduced them to our OEM & ODM production process (see full service page). We created digital CAD patterns, shared 3D mock-ups, and confirmed every dart, pleat, and hem depth through photos and video calls.

Result? Their next sample achieved approval on the first round. They launched the capsule successfully with 300 units in three colors, and re-ordered within two months. The client later told us, “The biggest difference was that Linenwind understood our design language clearly.”

This case proves that proper communication is not just an operational formality — it’s a strategic advantage that saves time, money, and brand reputation.

How to Build an Effective Communication Workflow

Establishing the right workflow is as important as having the right information. Here a practical guide we use with our clients at Linenwind to streamline communication for Custom Linen Dress development.

Step 1: Centralize All Files

Use one shared platform (Google Drive, Dropbox, Notion, or our secure client portal). Organize folders by style → version → sample → bulk. Always keep “latest” folders and archive old versions.

Step 2: Schedule Regular Updates

Set fixed weekly checkpoints (e.g., every Friday 3 PM China time) for updates on sample progress, revisions, and QC feedback. Consistency prevents surprises.

Step 3: Visualize Feedback

Rather than writing long paragraphs, mark feedback directly on photos or PDFs. Use colored highlights: red = change, green = approved, yellow = clarify.

Step 4: Document Everything

Keep written confirmation for every decision — even small ones (like button size or zipper color). This documentation protects both sides if disputes arise.

Step 5: Confirm Before Bulk

After final pre-production sample approval, sign a confirmation sheet including fabric batch # and measurements. We then freeze all details in our system before bulk production begins.

By adopting this structured communication workflow, you can work efficiently across time zones and cultural contexts — transforming communication from a risk into an asset.

Integrating Digital Tools for Better Design Communication

Modern fashion manufacturing benefits greatly from digital collaboration tools. When creating a Custom Linen Dress, technology helps bridge the gap between creative intent and production reality.

3D Design Software

Tools like CLO3D or Browzwear allow designers to simulate how linen drapes, stretches, and moves. These files can be shared directly with manufacturers like Linenwind, reducing sampling rounds.

Digital Pattern Files

Export patterns in DXF (AAMA) or Gerber formats so that the factory can import them into their CAD systems. At Linenwind, our in-house CAD team can adjust patterns digitally to correct tolerances or seam lines.

PLM (Production Lifecycle Management) Systems

Brands with larger collections can use PLM systems to manage design iterations, version history, BOMs, and QC approvals. Even small brands can use spreadsheets or free PLM tools for better traceability.

Instant Messaging Channels

For day-to-day clarifications, establish an official group chat (e.g., WeChat or Slack) including your designer, pattern maker, and account manager. Quick visual clarifications can prevent delays.

Technology doesn replace human clarity — it enhances it. Combine these tools with structured documentation to achieve precise, efficient communication.

Common Questions About Communicating with Manufacturers

Q1. How detailed should my first brief be?

As detailed as possible. Include all visual and measurement data. A strong brief shortens sampling time dramatically.

Q2. What if I don’t have technical experience?

That’s where Linenwind helps. Our design and technical team translates creative sketches into production-ready tech packs. With 20 years of experience, we guide you through the OEM process step by step.

Q3. Can I send just a photo of a dress I like?

Yes — as a starting point. We’ll develop a pattern and sampling plan based on your photo and measurements.

Q4. How can I ensure my intellectual property is protected?

Sign NDAs before sharing original designs. At Linenwind, we honor strict confidentiality for all OEM clients.

Q5. Can you help with fabric sourcing too?

Absolutely. We source European and Chinese linen from certified mills, provide swatches, and handle pre-washing to control shrinkage.

Q6. What your MOQ for Custom Linen Dresses?

Our minimum order quantity is 60 pieces, perfect for small brands and wholesalers testing new collections. You can view our collection page here: Custom Linen Dresses.

The Bigger Picture — Communication as Brand Value

Clear communication does more than prevent mistakes — it defines your brand professionalism. When you partner with an experienced Custom Linen Dress Manufacturer like Linenwind, the clarity of your communication signals reliability, seriousness, and respect for craftsmanship.

We’ve observed that brands maintaining structured communication channels tend to:

Approve samples 30 % faster

Reduce revisions by 40 %

Increase supplier trust and priority scheduling

In today competitive B2B fashion market, speed and precision matter. Factories prioritize brands that communicate well because their projects run smoothly. That why we at Linenwind encourage clients to treat communication as a strategic advantage — not a bureaucratic burden.

Final Call to Action

If you’re planning to develop your own Custom Linen Dress collection and want to avoid the communication pitfalls discussed above, reach out to us at Linenwind today.

Visit our OEM & ODM service page → Full-Service Clothing Manufacturer

Explore our product collection → Custom Linen Dresses

Or contact us directly → Contact Us

We’ll assign you a dedicated account manager who will guide you through fabric selection, pattern approval, sampling, and bulk production — with full transparency and real-time updates.

Let turn your design vision into reality — without misunderstandings.