2025 Linen Fashion Forecast: Why Partnering with Top Custom Linen Clothing Manufacturers Matters

- Share

- Issue Time

- Oct 27,2025

Summary

Explore the 2025 linen fashion forecast and learn why partnering with trusted linen clothing manufacturers like Linenwind ensures sustainable, stylish, and scalable growth.

Introduction

In 2025, the fashion world is undergoing a meaningful shift — one grounded in sustainability, natural fibres, and intelligent partnerships. At the heart of this transformation lies linen, the breathable, durable, and eco-friendly textile that is commanding attention. For brands, retailers and private-label ventures alike, working with the right linen clothing manufacturers is no longer just a tactical choice — it’s a strategic imperative. In this piece, we’ll explore the 2025 linen fashion forecast, show why the fabric is trending, and critically why selecting top custom linen clothing manufacturers matters — especially when you partner with a true expert like Linenwind.

Why Linen is Poised for a Breakthrough in 2025

There are compelling reasons linen is set to dominate wardrobes and sourcing strategies in 2025:

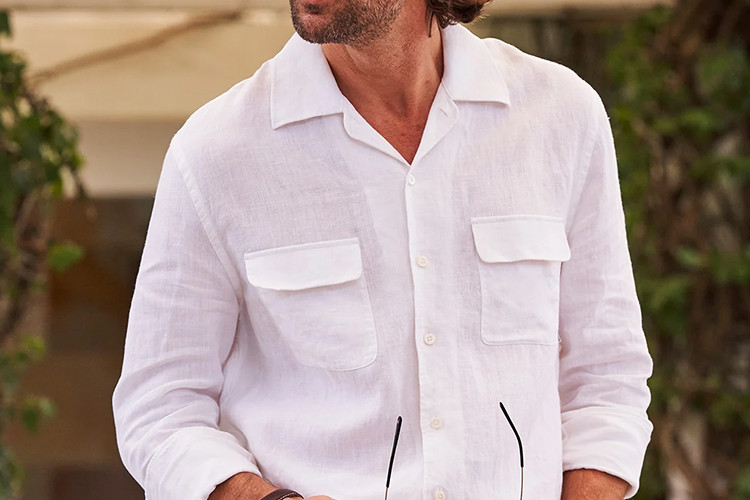

Breathability & comfort: Industry editorial sources highlight linen’s strong performance in warm-weather seasons thanks to its natural breathability and ease of wear. For example, a trend article notes that linen shirts and wide-leg pants are among the top picks for spring/summer-2025 wardrobes.

Elevated textures and blends: According to trend-forecast-ing body Peclers Paris, linen blended with cotton or wool, or treated for crisp, “sophisticated natural” draperies, is singled out among the key Spring-Summer 2025 fabric directions.

Sustainability credentials: Fashion editors are increasingly pointing to linen as a preferred natural fibre in the eco-conscious space.

Versatility across silhouettes: From oversized linen dresses to tailored linen pants and vests, the material is being reinterpreted across categories. Articles highlight wide-leg linen trousers, cargo styles, tailored linen pieces as central to the 2025 update.

Together, these dynamics mean that brands and retailers sourcing linen collections need to think beyond commodity ordering. They must partner with custom linen clothing manufacturers who can deliver on performance, design, customisation, and ethical production.

Elevated textures and blends: According to trend-forecast-ing body Peclers Paris, linen blended with cotton or wool, or treated for crisp, “sophisticated natural” draperies, is singled out among the key Spring-Summer 2025 fabric directions.

Sustainability credentials: Fashion editors are increasingly pointing to linen as a preferred natural fibre in the eco-conscious space.

Versatility across silhouettes: From oversized linen dresses to tailored linen pants and vests, the material is being reinterpreted across categories. Articles highlight wide-leg linen trousers, cargo styles, tailored linen pieces as central to the 2025 update.

Together, these dynamics mean that brands and retailers sourcing linen collections need to think beyond commodity ordering. They must partner with custom linen clothing manufacturers who can deliver on performance, design, customisation, and ethical production.

What Brands Should Look for in Linen Clothing Manufacturers

When your business objective involves launching or scaling linen-based lines, partnering with capable linen clothing manufacturers becomes the difference between success and underwhelming results. Here are the major selection criteria:

Design and sampling capability: You need custom design, mood-board development, CAD prototyping, and sample runs. The top linen clothing manufacturers will offer in-house design support and rapid sampling to test market concepts and volume fabrics.

Quality assurance and traceability: From yarn selection through weaving, dyeing, finishing, and garment construction, you want rigorous QA systems. Real‐time communication, inline inspections, and defect management distinguish leading manufacturers.

Flexibility and low MOQ: Smaller brands or capsule collections benefit from low minimum order quantities (MOQs). Working with manufacturers that support small-batch runs allows for market testing and an agile response.

Supply-chain transparency & sustainability: With linen’s eco-credentials under the spotlight, your sourcing partner should align with responsible production, ethical labour practices, and environmental metrics.

Full-service OEM/ODM support: From design through packaging, labeling, and private-label branding, the most capable linen clothing manufacturers provide turnkey solutions, allowing you to focus on brand & marketing rather than micromanaging production details.

Speed and capacity balance: Whether you’re launching 60 pieces or scaling to thousands, your manufacturing partner should offer both agile small batch capability and scalable capacity.

Fabric expertise & sourcing: The manufacturer should understand linen’s properties: fibre qualities, weight variations, blends, French-linen vs. other origins, finishing treatments (e.g., washing, softening, anti-wrinkle). A partner that simply uses “linen” generically may compromise hand-feel or durability.

Design and sampling capability: You need custom design, mood-board development, CAD prototyping, and sample runs. The top linen clothing manufacturers will offer in-house design support and rapid sampling to test market concepts and volume fabrics.

Quality assurance and traceability: From yarn selection through weaving, dyeing, finishing, and garment construction, you want rigorous QA systems. Real‐time communication, inline inspections, and defect management distinguish leading manufacturers.

Flexibility and low MOQ: Smaller brands or capsule collections benefit from low minimum order quantities (MOQs). Working with manufacturers that support small-batch runs allows for market testing and an agile response.

Supply-chain transparency & sustainability: With linen’s eco-credentials under the spotlight, your sourcing partner should align with responsible production, ethical labour practices, and environmental metrics.

Full-service OEM/ODM support: From design through packaging, labeling, and private-label branding, the most capable linen clothing manufacturers provide turnkey solutions, allowing you to focus on brand & marketing rather than micromanaging production details.

Speed and capacity balance: Whether you’re launching 60 pieces or scaling to thousands, your manufacturing partner should offer both agile small batch capability and scalable capacity.

By carefully vetting potential partners across these criteria, you align your sourcing strategy with 2025’s linen fashion momentum. The next section shows how I position Linenwind as such a partner.

Linenwind – Your Partner in Custom Linen Clothing

At Linenwind, we specialise in custom linen garment manufacturing and private-label services designed for forward-thinking brands that value quality, sustainability, and flexibility.

📍 Location: China

About us

With over 20 years of apparel manufacturing experience, we’ve refined the art and science of linen production — from material sourcing and fabric development to full-package design, sampling, and packaging. We understand the unique attributes of linen and how to leverage them for premium performance and aesthetic appeal.

Our key advantages:

🌿 Focus on eco-friendly linen and sustainable production

⚙ Full in-house OEM & ODM services covering design, sampling, production, and packaging

🛎 Low MOQ of 60 pieces for easy market testing and small batch runs

🔍 Rigorous quality assurance with real-time communication throughout production

🤝 Dedicated account managers for personalised service and timely delivery

By choosing Linenwind as your manufacturing partner, you gain access to commitment to cost efficiency, quick turnaround for sample or capsule lines, custom branding, and the agility to ride the linen clothing manufacturers' trend wave.

Why Partnering with a Top Custom Linen Clothing Manufacturer Matters Now

With the 2025 forecast firmly signalling linen as a seasonal staple, here’s why your choice of manufacturer is strategic:

2. Control over fabric innovation: Top manufacturers can offer development of linen blends, specialised finishes (soft-wash, garment-dye, pre-wrinkle textures) and custom colours aligning with the Spring/Summer 2025 direction (neutral tones, natural textures, dry & fresh surfaces).

3. Branding differentiation: As more brands shift to linen, differentiation will depend on execution — fit, finish, branding, and packaging. A manufacturer offering full private-label packaging, custom trims, and branding helps your offering stand out.

4. Sustainability alignment: As consumers and retailers emphasise green credentials, working with a manufacturer committed to eco-friendly linen and responsible production elevates your brand credibility.

5. Cost efficiency & quality assurance: The right partner balances competitive cost, consistent quality, and scalability. Poorly executed linen garments can wrinkle excessively, shrink, or wear poorly — undermining brand trust.

6. Flexibility for small batches & scaling: Whether you’re testing with 60 pieces or scaling to thousands, a manufacturer who supports both gives you the flexibility to pilot, learn, and scale without switching suppliers mid-journey.

7. Future-proofing your supply chain: As linen becomes more prominent, reliable supply, fabric availability, and manufacturing capacity will grow more competitive. Partnering early with exemplary linen clothing manufacturers gives you a strategic advantage.

1. 1. Speed to market & trend relevance: The desire for “linen everything” is real. To capitalise, you need a manufacturing partner who can turn concepts into finished samples rapidly, supporting agile retail cycles or direct-to-consumer launches.

2. Control over fabric innovation: Top manufacturers can offer development of linen blends, specialised finishes (soft-wash, garment-dye, pre-wrinkle textures) and custom colours aligning with the Spring/Summer 2025 direction (neutral tones, natural textures, dry & fresh surfaces).

3. Branding differentiation: As more brands shift to linen, differentiation will depend on execution — fit, finish, branding, and packaging. A manufacturer offering full private-label packaging, custom trims, and branding helps your offering stand out.

4. Sustainability alignment: As consumers and retailers emphasise green credentials, working with a manufacturer committed to eco-friendly linen and responsible production elevates your brand credibility.

5. Cost efficiency & quality assurance: The right partner balances competitive cost, consistent quality, and scalability. Poorly executed linen garments can wrinkle excessively, shrink, or wear poorly — undermining brand trust.

6. Flexibility for small batches & scaling: Whether you’re testing with 60 pieces or scaling to thousands, a manufacturer who supports both gives you the flexibility to pilot, learn, and scale without switching suppliers mid-journey.

7. Future-proofing your supply chain: As linen becomes more prominent, reliable supply, fabric availability, and manufacturing capacity will grow more competitive. Partnering early with exemplary linen clothing manufacturers gives you a strategic advantage.

For brands keen on aligning with the 2025 linen trend while managing risk and cost, the right manufacturing partner isn’t a nice-to-have — it’s a differentiator.

What to Expect in Linen Collections in 2025

When planning your next collection with linen, here are the product- and design-direction opportunities you should leverage:

Colour palette and texture: Expect neutral tones (ecru, sand, butter yellow), soft contrasts (tomato red accent), and natural dyeing.Texture wise: dry-hand linen, linen-blends with light lustre, artisan irregularities are in.

Silhouette variation:

Breezy dresses and tunics: Flowing linen dresses continue to dominate Spring/Summer 2025.

Wide-leg linen trousers and relaxed tailoring: Stylish comfort is key; articles show the strong rise of wide-leg linen pants.

Linen vests and tailored overlays: Designers are reimagining linen in structured pieces like vests and jackets

Functional blends: Not all linen is 100% pure fibre — manufacturers are increasingly blending linen with cotton, wool or lyocell to create season-less, higher-durability fabrics.

Sustainable features & finishes: Pre-washed linen, low-impact dyes, minimal finishing, recyclable packaging — all enhancements expected from conscientious manufacturing.

Silhouette variation:

Breezy dresses and tunics: Flowing linen dresses continue to dominate Spring/Summer 2025.

Wide-leg linen trousers and relaxed tailoring: Stylish comfort is key; articles show the strong rise of wide-leg linen pants.

Linen vests and tailored overlays: Designers are reimagining linen in structured pieces like vests and jackets

Functional blends: Not all linen is 100% pure fibre — manufacturers are increasingly blending linen with cotton, wool or lyocell to create season-less, higher-durability fabrics.

Sustainable features & finishes: Pre-washed linen, low-impact dyes, minimal finishing, recyclable packaging — all enhancements expected from conscientious manufacturing.

Private label and capsule readiness: Because the material and trend are clear, brands are launching linen capsules and private label lines. This underscores the importance of partnering with linen clothing manufacturers who support small batch, custom branding and turnkey services.

By aligning your design roadmap with these trends and the capabilities of your manufacturing partner, you ensure your linen collection is both on-trend and differentiated.

How to Work with Linenwind: Our Collaboration Process

Here’s a step-by‐step overview of how we at Linenwind facilitate a seamless collaboration with brands seeking top-tier linen clothing manufacturing:

Step 2 – Fabric sourcing & development: We present linen fabric options — from 100% European flax linen to blends. We advise on finishes, weights, hand-feel, shrinkage control, and sustainable credentials.

Step 3 – Design & sampling: Our in-house design & CAD team converts your sketches or mood board into digital patterns. We create samples using the approved fabric, trimming, labels, and packaging elements. You review, we iterate.

Step 4 – Pre-production & quality plan: Once samples are approved, we prepare pre-production run sheets. We set quality checkpoints, inline inspections, and real-time communication to keep you updated.

Step 5 – Full production: With our in-house facilities (cutting, sewing, finishing), we manage the production run. Whether you’re producing 60 pieces or 6,000, we scale accordingly. A dedicated account manager ensures your timelines are met.

Step 6 – Branding, packaging & delivery: We support private-label trims, folding styles, and packaging customisation. Once QA is complete, goods are shipped to your warehouse, or we coordinate logistics per your preference.

Step 7 – After-sales & future planning: Post-shipment, we gather feedback, monitor performance, and plan next-phase opportunities (e.g., expansion to dresses, vests, linen outerwear).

Step 1 – Brief & Concept: Share your vision for your linen line. We discuss target market, silhouettes, fabric preferences (pure linen or blends), colours, MOQ (Low MOQ: 60 pieces), branding, and packaging objectives.

Step 2 – Fabric sourcing & development: We present linen fabric options — from 100% European flax linen to blends. We advise on finishes, weights, hand-feel, shrinkage control, and sustainable credentials.

Step 3 – Design & sampling: Our in-house design & CAD team converts your sketches or mood board into digital patterns. We create samples using the approved fabric, trimming, labels, and packaging elements. You review, we iterate.

Step 4 – Pre-production & quality plan: Once samples are approved, we prepare pre-production run sheets. We set quality checkpoints, inline inspections, and real-time communication to keep you updated.

Step 5 – Full production: With our in-house facilities (cutting, sewing, finishing), we manage the production run. Whether you’re producing 60 pieces or 6,000, we scale accordingly. A dedicated account manager ensures your timelines are met.

Step 6 – Branding, packaging & delivery: We support private-label trims, folding styles, and packaging customisation. Once QA is complete, goods are shipped to your warehouse, or we coordinate logistics per your preference.

Step 7 – After-sales & future planning: Post-shipment, we gather feedback, monitor performance, and plan next-phase opportunities (e.g., expansion to dresses, vests, linen outerwear).

By working with us, your brand benefits from a full-service partnership rooted in expertise, agility and shared vision for linen.

Key Takeaways for Brands & Retailers

To summarise, if you’re planning or expanding a linen-based apparel line in 2025, here’s what you should keep in mind:

Linen is trending strongly – consumers and editors alike are embracing linen for its natural, breathable, and stylish qualities.

The manufacturing partner matters – your success depends heavily on choosing linen clothing manufacturers who can deliver design flexibility, quality assurance, renewable fabrics, and agility.

Low MOQ capability is a strategic advantage – launching with 60 pieces or small batches allows you to test the market, refine your offering, and scale confidently.

Full-service manufacturing wins – from fabric sourcing to packaging, custom branding, and private label, you’ll gain differentiation and speed.

Sustainability isn’t optional – the material itself lends credence to eco-messaging, but your manufacturing partner must deliver on production ethics, traceability, and responsible finishing.

Trend alignment matters – by working with a partner who understands the 2025 fabric and silhouette direction, your linen collection will feel current, elevated, and relevant.

At Linenwind, we’re ready to partner with you — whether you’re a startup launching your first linen capsule or an established brand scaling into linen basics, dresses, shirts, or tailored pieces. Our focus on eco-friendly linen, full in-house OEM/ODM services, low MOQ of 60 pieces, rigorous quality assurance, and dedicated service means we’re the reliable manufacturing partner you need.

If you’re ready to bring your linen collection to life in 2025 and want to work with one of the leading linen clothing manufacturers, let’s talk. Visit our product collection: Custom Linen Shirts collection to explore. Check our OEM/ODM services page: Full-Service Clothing Manufacturer. Then reach out via our Contact Us page — we’re ready to help you design, sample, and deliver your next linen success story.

Partnering with the right manufacturer now means you’ll be ahead of the curve — not just catching a trend, but owning it.